The Definitive Guide for Steel Infill Panels

Table of ContentsNot known Details About Steel Infill Panels Some Known Incorrect Statements About Steel Infill Panels The Only Guide for Steel Infill Panels

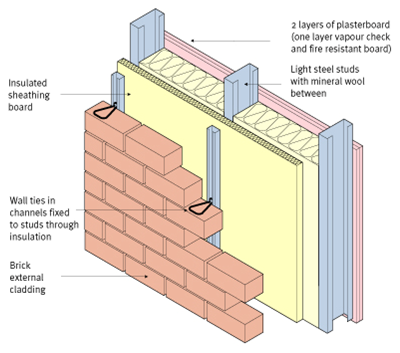

The glazing module need to be such that an affordable thickness of glass can be specified. The jointing issue with infill panels happen generally at its joint with the structural frame and allocation for moisture or thermal movement is usually achieved by using an appropriate mastic or sealant. Stonework infill panels of contemporary tooth cavity construction can be used to maintain traditional attributes and to attain high requirements of sound and also thermal insulation as well as fire protection. steel infill panels. Stonework walls are connected to the architectural frame with wall connections cast right into the concrete columns or with a purpose-made cladding assistance system. A lot of infill panels are supplied as a maker's modular system, given that purpose-made panels can be uneconomic, yet whichever technique is picked the style intends remain consistent; that is, to offer a panel which satisfies all the required navigate to these guys functions and also has a reduced long-lasting upkeep factor.

Excitement About Steel Infill Panels

One of the upkeep problems come across with infill panels as well as possibly to a minimal extent with the concrete cladding, is the cleansing of the faade and also particularly the glazing. All buildings gather dust, the impacts of which can differ with the product: concrete as well as masonry often tend to accept dirt and also climate all-natural, whereas resistant materials such as steels and glass do decline and also can rust or come to be less effective. If glass is permitted to end up being coated with dirt its aesthetic look is much less acceptable, its optical efficiency decreases considering that clearness of vision is reduced as well as the beneficial infiltration of natural daylight diminishes.

Gain access to for cleaning glazed areas can be exterior or internal. Windows at ground level present no access issues and present just the question of choice of method such as hand towels or telescopic posts with squeegee heads. Reduced and also medium-rise frameworks can be reached by ladders or a mobile scaffold tower as well as normally present extremely few problems. Skyscraper structures need cautious factor to consider. External accessibility to windows is gained by making use of a cradle suspended from roof degree; this can be in the kind of a short-lived system consisting of counterweighted cantilevered beams where the cradle is suspended. Long-term systems, which are incorporated as part of the building style, are much more reliable as well as contain a track on which a mobile cart is placed and also from which davit arms can be forecasted past the roofing side to support the cradle.

Interior accessibility for cleaning the external glass face can be visit homepage attained by utilizing home windows such as relatively easy to fix sashes, horizontal as well as vertical gliding sashes, but the designer is site here limited in his selection to the reach feasible by the ordinary person. It can not be overemphasized that such windows can be a very harmful danger unless carefully developed so that all parts of the glazed area can be gotten to by the person cleaning up the home windows while standing securely on the floor. Introduction The functions of an infill panel are as listed previously for cladding panels as a whole. Infill panels are light-weight and typically glazed to give great interior natural day illumination conditions.

The Facts About Steel Infill Panels Revealed

The jointing problem with infill panels happen mostly at its junction with the architectural framework as well as allowance for dampness or thermal motion is normally attained by utilizing an ideal mastic or sealer - steel infill panels. Masonry infill panels of contemporary tooth cavity building can be utilized to protect traditional attributes and also to obtain high requirements of audio and also thermal insulation and also fire protection. Masonry walls are linked to the architectural framework with wall surface ties cast into the concrete columns or with a purpose-made cladding support group. The majority of infill panels are provided as a producer's modular system, since purpose-made panels can be uneconomic, yet whichever technique is chosen the style intends remain consistent; that is, to give a panel which meets all the called for functions as well as has a reduced long-term upkeep factor.